All couplings transmit torque and angular velocity. Flexible variations compensate for misalignment. Many of the latter even address vibration and improve system dynamics. Design considerations include machine or installation construction and backlash, torsional stiffness, damping, inertia, torque ratings, maximum rpm, size, misalignments, ease of installation, robustness, and cost. For power transmission (as in motors for […]

r+w america

R+W safety couplings for wastewater applications

R+W has developed a standard model of corrosion proof ball detent safety coupling for clarifier drives in water treatment plants. The industry requires a well sealed, high-grade stainless steel mechanism to stand up to harsh conditions, resulting in the specific design criteria. The function of the ball detent torque limiter is to disengage the driveline […]

How do I ensure coupling alignment for precision motion control applications?

*Below is an excerpt from a Design World webinar presentation by Andy Lechner of R+W America. Here, Lechner covers some best practices for handling coupling installation in precision motion control applications. Coupling alignment is important in smaller devices, especially when there’s precision or dynamic motion that needs to be transmitted. If you think about the […]

Insert properties in precision grade elastomer couplings

By Joyce Laird, Contributing Editor Andy Lechner, Product Manager for R+W America, explains that it is important to look at how to break down the classifications of elastomer insert couplings to better understand how everything fits into industry use today. He says that elastomer insert couplings generally fall under one of two main classifications: “standard” […]

Robust jaw couplings make for easy water testing

Testing water samples is an important and critical business, so when Hach Co., Loveland, Colo.—a provider of water quality testing and water quality analysis—was designing one of its signature samplers, it wanted a design that was maintenance free and wouldn’t cause any problems. That’s why Hach turned to R+W America, as it worked on the […]

R+W expands offerings to include flexible disc pack couplings

R+W, which is known for flexible shaft couplings for servodrives, is expanding its offerings to include flexible disc pack couplings. Its new series of Survivor couplings is best suited for demanding industrial power transmission systems. The Bensenville, Ill.-based company has spent more than two decades creating flexible bellows couplings that offer high torsional stiffness, low […]

Intermediate Coupling Spacers

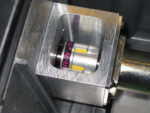

SERVOMAX elastomer couplings feature a specially calibrated polyurethane insert, which is preloaded between precision machined driving jaws. They have high torque density, are low in cost, and are used for vibration damping, shock absorption, and compensation for some small amounts of shaft misalignment. Occasionally, machine layouts and mounting arrangements simply do not allow for installers […]

Maintenance free couplings for heavy engineering

Extreme temperature ranges, high pollution levels, high vibration levels, and 24/7/365 operation call for engineered drive components which can take the abuse. Extending component maintenance intervals is a priority, since industrial gearboxes, electric motors, bearings, and drive shafts typically require at least partial disassembly and replacement of wear parts. A new solution involves zero maintenance, […]

Compact safety coupling

Making use of the existing EKL line of compact elastomer couplings, the SLE safety coupling offers a compact, flexible and vibration damping option with integral torque overload release. Designed for aggressive servo driven applications, the SLE is backlash free, relying on preloads and frictional connections, along with a precision molded, wear resistant, polyurethane insert to […]

Compact stainless steel bellows couplings

The BKS series of stainless steel, welded bellows couplings are up to 1/3 shorter in length, reducing moment of inertia and saving space. Manufactured in Germany, the BKS makes use of 1.4301 (304) stainless steel hubs, precision machined to a high level of concentricity. Laser welded while mounted onto a common shaft to guarantee straightness, […]