Properties low cost good concentricity low backlash due to key connection Temperature Range dependent on the elastomer insert Design Two concentrically machined hubs with curved jaws, keyways, and set screws 5x elastomer segments press fit for zero backlash Material Hubs: GGG40 Elastomer insert: wear-resistant thermally stable TPU R+W www.rw-america.com/product/ek1/

Elastomer

ROTEX goes digital- LIVE EVENT

You know ROTEX as a versatile and reliable elastomer coupling. Now you have the chance to get to know new sides of the globally top-selling shaft coupling: The ROTEX goes digital. It measures torque and speed, shows the values on a display, and transmits the measuring results wirelessly to your smartphone or PC. This will […]

Ringfeder elastomer jaw couplings GWE, TNM, TNS & TNB

Ringfeder’s Elastomer Jaw Couplings of the RINGFEDER GWE, TNM, TNS, and TNB series — originating in the proven GERWAH and TSCHAN series – meet the highest performance and durability requirements in a wide range of sectors, e.g. the steel and metal industry, drive and conveyor technology, power generation, machine tool, packaging and printing machine construction […]

Ringfeder releases GWE 5117 servo-coupling for hollow shaft connections

RINGFEDER has recently released its GWE 5117 series of elastomer jaw servo-couplings, featuring a new hub design. With its partially slit hub located directly under the jaws and two screw clamps, this model eliminates radial loads on the shaft and achieves uniform power transmission. This hub design also prevents premature wear and system failure. Designed […]

How to handle elastomeric coupling creep

In engineering, one of the more common questions ABB gets on the Raptor coupling deals with the twisting of the element. Many users incorrectly assume this is a sign of failure. This phenomenon is common to any elastomeric coupling and is the result of a process called creep. Here, we take a look at several […]

Ringfeder’s Elastomer Jaw Couplings GWE 5113

Torsionally flexible, backlash-free elastomer couplings with single-slit aluminum clamping hubs, highly compact design, and outstanding concentricity for vibration and shock damped, uniform power transmission. 7 different sizes Bore Diameter d: 4-56 mm (0.157-2.205-in.) Outer Diameter D: 24.5-94.5 mm (0.966-3.270-in.) Overall Length L: 32-102 mm (1.259-4.016-in.) Rotational Speed nmax: 4,000-15,000 1/min Torque T: 3-560 Nm (2.21-413.04 […]

Ruland jaw couplings for servo motors

Zero-backlash jaw couplings from Ruland have high dampening capabilities, can accommodate all forms of misalignment, and are highly customizable. They are well-suited for servo motors that are often used in precise positioning applications found in semiconductor, solar, medical, and robotics. Each application that uses a servo motor will have different performance requirements such as rpm, […]

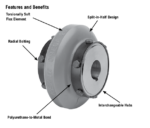

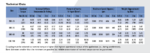

Rexnord Omega elastomeric couplings

The unique split-in-half flex element and reversible hubs significantly decrease total costs by reducing inventory and assembly time. Rexnord Omega couplings are non-lubricated, material-flexing couplings utilizing a specially formulated polyurethane material engineered for maximum durability, strength, and fatigue resistance. The Rex Omega HSU coupling (green) is specifically designed for hot and humid conditions. Rexnord is […]

EDC elastomer drive shaft coupling from GAM

The EDC is a low-cost elastomer drive shaft coupling with split hubs. Provides vibration/resonance dampening and compensation for shaft misalignments. Bore range: 8 mm – 45 mm / Torque range: 25 Nm – 110 Nm. Major Features • Elastomer drive shaft coupling. • Customized lengths up to 20-ft • Low cost and quick standard delivery […]

Ringfeder elastomer jaw couplings

The rotationally resilient couplings of the RINGFEDER series GWE, TNM, TNS, and TNB are puncture-proof and flexible in all directions and therefore compensate for angular, parallel, and axial shaft misalignments of the connected machines. Misalignments can be caused for example by inaccurate assembly, heat movements, or settling phenomena. Avoiding torsional vibration By virtue of the […]