August 27, 2017 update: The full-length technical feature on this servo-coupling topic of damping and gain setting is now live.

New technological improvements in servomotors have spurred dramatic improvements in response frequencies. The catch is that vibration (and hunting) tend to arise when designers apply high gain settings to servo systems and use advanced couplings with high torsional stiffness — such as disc or bellows-type couplings, for example.

One way to resolve hunting in setups with high gain settings is to use couplings with vibration-damping capabilities. Here, couplings with hydrogenated nitrile butyl rubber (HNBR) center elements are one option to make servo systems for precision automation tasks (as those in semiconductor manufacturing) more responsive. Sometimes called high-gain rubber couplings, these have an integrated structure that includes aluminum hubs on both ends molded with vibration-reducing HNBR to prevent backlash but stay flexible. The rubber-lined claw structure optimizes torsional rigidity as well as damping.

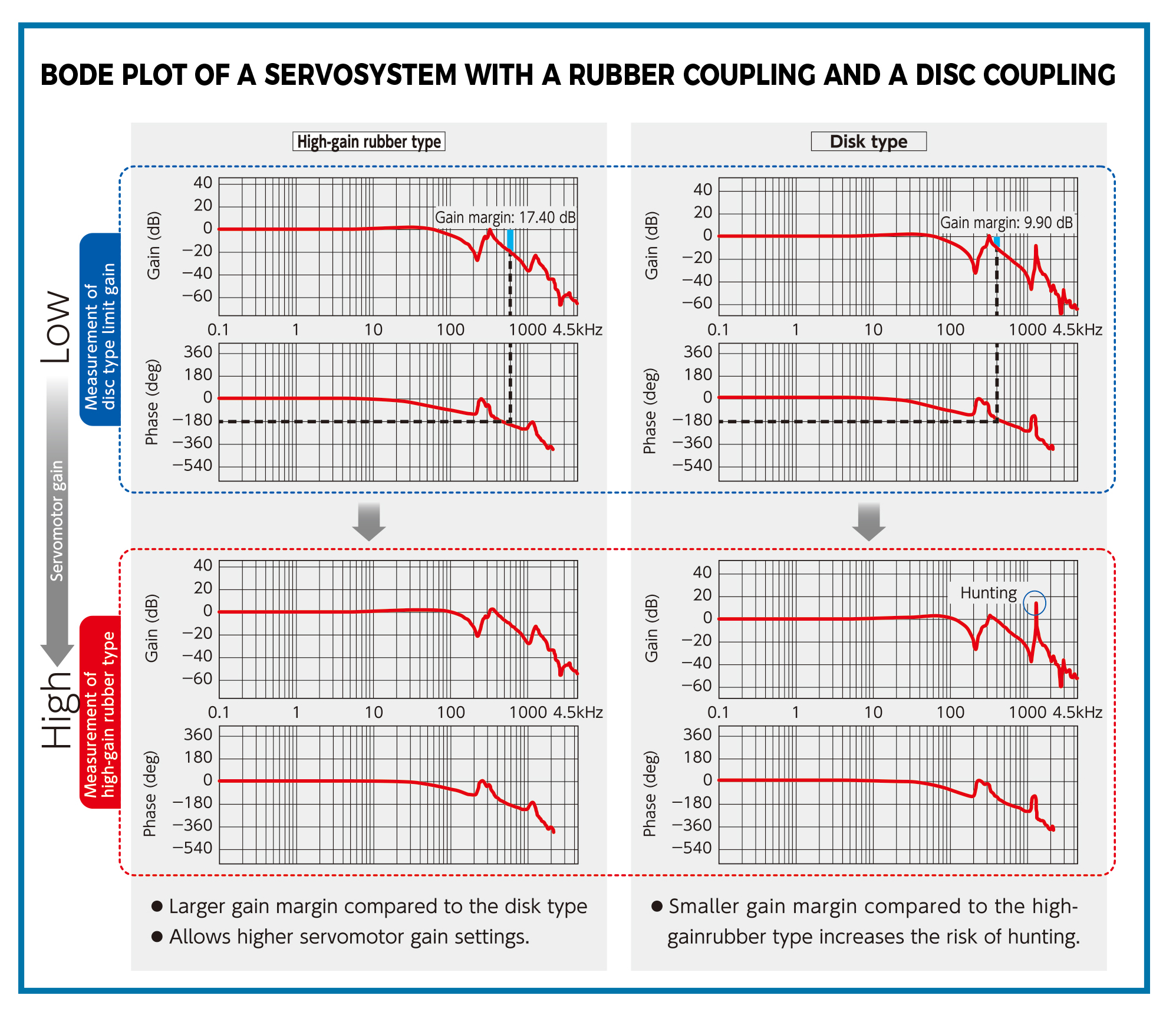

Laboratory testing and the resultant Bode plots show how high-gain rubber couplings increase servomotor gain beyond the capacity of comparable couplings with high torsional stiffness.

Gain width between 0 dB and the point at which there’s a phase delay in the Bode plot is -180° and this is called the gain margin. General guidelines for servo systems recommend gain margins between 10 and 20 dB. As servomotor gain rises, gain margin decreases. When the gain margin falls below 10 dB, hunting tends to occur.

Consider the limit gain (the servo gain at which hunting occurs) of assemblies using high-gain rubber-type couplings. The value of 17.40 dB surpasses that of other coupling types. Plus because the gain margin is above 10 dB, the servomotor gain of the rubber-insert couplings effectively shortens stabilization time and increasing throughput. More specifically, a system with a 12-msec limit gain might see improvement to a 3-msec limit gain simply by switching to a rubber-type coupling. This suppresses hunting and minimizes time for stabilization.

This information on high-gain rubber couplings is provided by Paulo Castelo, technical solutions supervisor at NBK America. Stay tuned to Design World’s own couplingtips.com in the coming weeks for the full feature on servomotor couplings and the relationships between stiffness, hunting, damping, and stabilization considerations.

August 27, 2017 update: The full-length technical feature on this servo-coupling topic of damping and gain setting is now live.

Leave a Reply