New configurations and solutions for extreme conditions.

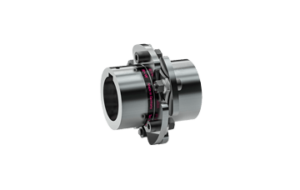

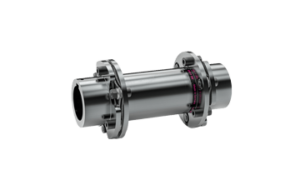

Robust and compact: R+W disc pack couplings are torsionally stiff, maintenance-free, and reliable even in some of the most difficult operating environments, including steel works, high-performance dynamometers, and industrial pump and process equipment. Fully metallic and made from high strength materials, they frequently operate in temperatures ranging from -30° up to 280° C.

R+W has recently performed a major overhaul and upgrade to its product range of torsionally stiff disc pack couplings. With this update, the coupling experts are bringing more options, special solutions, and mounting arrangements to the table, benefitting users like never before.

Anything is possible – from standard stock spacer lengths fit to a variety of end configurations to tailor-made solutions built from scratch to meet exact customer requirements. New sizes are also available, with catalog torque capacities up to 50,000 Nm and up to 100,000 Nm available on request.

Traditional disc coupling models with keyway connections and conical clamping rings (LP1 and LP4) are available in single or dual flex arrangements (version S or D) with the dual flex versions including a short “connection plate” between disc packs. The spacer versions (LP2 and LP3) offer standard lengths plus the option to be configured as custom length driveshafts. New split clamping hub (LP5) and fully split clamping hub (LPH) versions offer user-friendly mounting, with the LPH type allowing for the complete coupling to be installed and removed without disturbing the adjacent shafts.

Also new is the optional “XL hub” for keyway mounting, which allows for larger bores within a given coupling size. This helps to avoid unnecessary oversizing of couplings to fit onto relatively large diameter motor shafts, saving cost, weight, and installation space in many applications.

The new product data is already available here.

R+W

Leave a Reply