By David W. Neville, S.S. White Technologies, Inc.

In homes, small businesses, and large industrial settings, plumbing systems and drains need cleaning. In many of these settings drain cleaning consists of pouring chemicals down the pipes every few years. In other places and businesses, drain cleaning is a much more substantial job.

Restaurants and food businesses put undue stress on their drain systems with all of the grease and food waste they discard every day, requiring heavy-duty industrial drain cleaning equipment to remove troublesome blockages.

In older homes or businesses that are located next to old trees and their root systems, the situation is similar, as tree roots can infiltrate drains and pipes, clogging them severely.

When blockages like tree roots or a longtime build-up of grease come into play, chemical solutions do no more than tickle blockages. This is why there are a wide variety of industrial drain cleaning devices on the market today – there is a need for machines that can clean severely blocked drains quickly, cheaply, and efficiently.

Types of Drain Cleaning Machines

Industrial strength drain cleaning machines can be divided into roughly three types: hydro-jetting machines, drain snakes, and power rodding machines.

Hydro-jetting is the process of using a high-pressured flow of water to scour the interior surfaces of the plumbing pipes. This removes scale, grease and other debris that has built up inside the pipe walls over time. Drain cleaning machines using this method work in more or less the same basic way. First, the operator inserts a hose that’s connected to a tank of water into the clogged pipe. The hose can withstand the high-pressured water that’s sent into the pipes, and a specialized machine pressurizes water from the tank. This hose then delivers a high-pressure jet of water into the pipe, the pressure of which varies depending on the condition of the pipes. In general, machines may pressurize the water up to a 5,000 psi or more and deliver as many as 20 gallons of water per minute. The process of removing the blockages from the pipe involves working with gravity. This type of machine can be quite effective at drain cleaning, but it does have downsides, including freezing in cold temperatures and the various dangers that can come along with using high pressure.

Perhaps the most common kind of drain cleaning machine is called a drain snake. Drain snaking has a simple operation that is often effective, especially for home plumbing use. Industrial strength drain snakes are, more or less, a long spring cable with corkscrew on the end, attached to a motor. The cable is inserted into the clogged pipe, and the motor feeds the cable into the pipe. With luck the cable or corkscrew at the end snags any blockages in the pipe and can then be pulled out with the blockages. This kind of drain cleaning machine is common, but it is often not suitable for more challenging drain cleaning applications.

The last of the three most common drain cleaning machines work via a method known as “power-rodding.” Developed as an alternative to drain snake machines, power rodding systems use a flexible metal cable that threads into drain systems and around bends and joints. A cleaning head with very sharp teeth is installed at the leading end of the cable. This cleaning attachment is sized to the diameter of the pipe being treated. An electric motor rotates the cable, causing the sharp cleaning head to turn at a high rate of speed. This action obliterates the obstruction blocking the pipe, shears off any protrusions such as tree roots and shaves away years of sludge buildup. The high-speed cutting tool shreds the obstructive material blocking the pipe into small fragments that are easily flushed away when the flow of water is introduced into the pipe.

While all three of these methods are viable depending on the application, all three have downsides and issues. However, one technology – flexible shafts – when applied to drain cleaning machines, can help to rectify many of these issues, and serve as a complement to other drain cleaning machines.

Flexible Shafts in Drain Cleaning

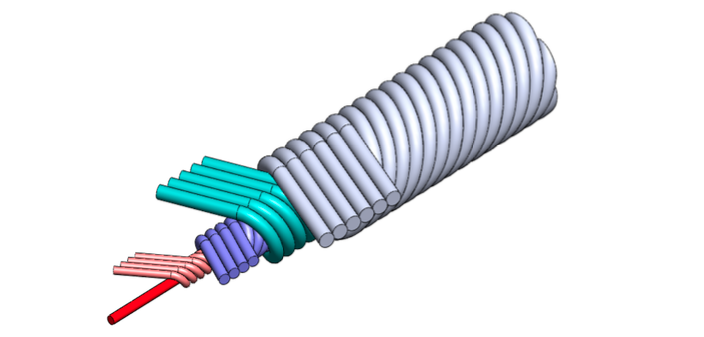

A flexible shaft is a precisely defined and configured nested group of springs, tightly wound so that it has torsional or rotational strength, as opposed to the tensile strength found in standard wire rope or cable to which flexible shafts bear a resemblance.

What makes flexible shafts specifically useful is that flexible shafts can bend, but also still rotate. In other words, a flexible shaft transmits rotary motion much like a solid shaft, but it can be routed over, under, and around obstacles that would make using a solid shaft impractical.

Flexible shafts are used in a number of applications, including advanced aerospace technologies. Their flexibility, combined with tensile strength, makes flexible shafts a force in the tight, twisted environments often encountered in drain cleaning.

When compared to other drain cleaning technologies, drain cleaning machines using flexible shafts are advantageous in that they are smaller, lighter and more flexible; easier to clean; and enable the use of a camera in drain cleaning.

Flexible shafts are as strong as other kinds of cables used in drain cleaning, but they are smaller and lighter, as well as more flexible. These characteristics are helpful in two ways. First, flexible shafts’ low weight and size is useful primarily for the operators of drain cleaning machines in using and transporting the equipment to the job site. The cables traditionally used in drain cleaning can be large and heavy, as well as difficult to transport. In addition, traditional drain cleaning cables, which more or less resemble extremely long, tightly wound open springs, are not very flexible. This can make maneuvering the cables through drains difficult. Flexible shafts are notably more flexible, so they can be useful in drain cleaning applications in which the clogged pipes are particularly bendy or hard to navigate with the stiffer traditional drain cleaning cables.

Another advantage flexible shafts have over traditional drain cleaning cables is that they are exceedingly easy to clean. Traditional drain cleaning cables are like large hollow springs – springs are by nature open to the air, so in drain cleaning, as the cable moves through the dirty drain, unclogging debris, it is likely for that debris to become lodged in and on the cable. Being that these cables are long and tightly wound, it is a hassle for drain cleaners to maintain them and keep them clean. Flexible shafts, on the other hand, are covered in a protective casing, making clean-up after a drain is cleaned much easier.

Lastly, flexible shafts can be advantageous to use over other drain cleaning methods in certain situations because they clean drains without water, which enables the use of a camera. When hydro-jetting, camera use is impossible due to the high volume of pressurized water used. Cleaning a drain using a machine based around a flexible shaft (or other dry cable) allows a camera to be fed into the drain just behind the spinning end of the cable. This can be helpful as it allows drain cleaners to see what exactly is blocking the pipe, enabling them to adjust their cleaning method if need be.

The Clog Dog

One notable example of flexible shafts being used in drain cleaning to great effect is their use by Clog Squad, a Michigan-based drain cleaning contractor. According to Clog Squad, it had been searching for a lighter, safer and easier way to clean drains, and found it in the flexible shaft.

The Clog Squad’s Clog Dog drain cleaning machine is based around the use of a flexible shaft to clean drains, and according to Clog Squad, the use of flexible shafts with the Clog Dog has made the job cleaner, safer, and way more effective.

Clog Squad gets its flexible shafts from S.S. White, one of only three flexible shaft manufacturers in the United States. S.S. White has helped Clog Squad cleaning by ensuring that its flexible shafts are always designed to exact specifications using proprietary software. The use of S.S. White’s flexible shaft has enabled Clog Squad great success while drain cleaning.

S.S. White

www.sswhite.net

Leave a Reply