By Ringfeder Editor

Earthquake-resistant construction is vital to keeping people safe and preventing economic losses in earthquake-prone regions. To ensure the safety of the public and infrastructure, it’s important to comply with all applicable earthquake codes and standards, which are consistently updated with data collected from recent earthquakes and related research.

Earthquake-resistant construction is vital to keeping people safe and preventing economic losses in earthquake-prone regions. To ensure the safety of the public and infrastructure, it’s important to comply with all applicable earthquake codes and standards, which are consistently updated with data collected from recent earthquakes and related research.

Numerous seismic standards have been developed worldwide, with most based on fundamental and proven approaches to earthquake-resistant design. These standards have varying technical requirements according to different geological conditions and regional building techniques. This variance has led to the development of different earthquake protection solutions including seismic base isolation, which has kept structures standing for over 1,000 years.

Ancient History

Seismic base isolation’s operating principle is to use specific structural elements that decouple a building’s superstructure and substructure. In the event of an earthquake, the substructure will move while the superstructure’s integrity is preserved. Base isolation has existed since 550 B.C.E. The Tomb of Cyrus the Great in Pasargadae (Iran) features two foundations that support the structure. Here’s how it works:

The lower foundation consists of stones bonded together with lime plaster and sand mortar.

The upper foundation is a large plate composed of polished stones. This plate is not connected to the lower foundation.

During an earthquake, the upper foundation freely slides upon the lower foundation.

Though ancient, the tomb has survived to the present day in one of the most seismically active regions on earth — a testament to the success of base isolation.

Modern Base Isolation Techniques

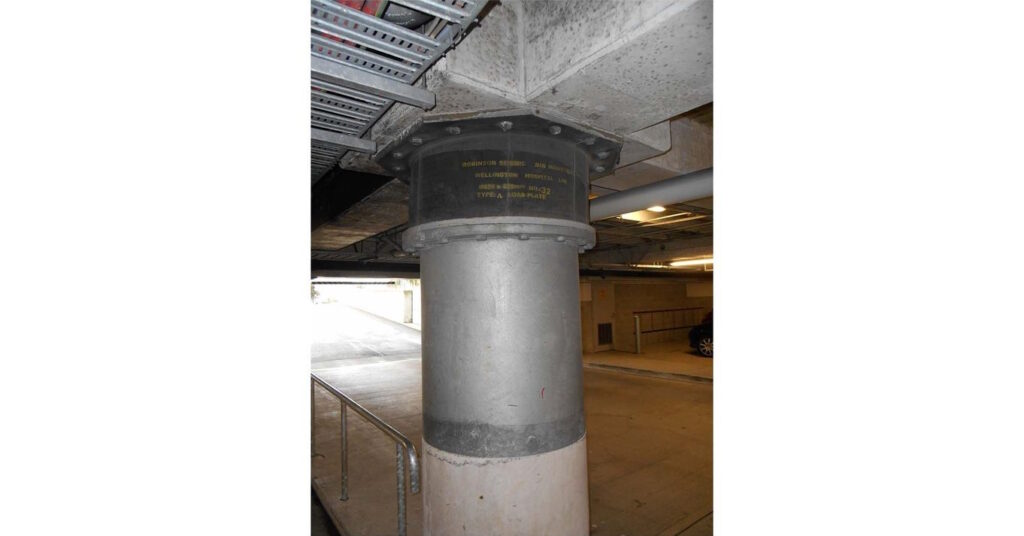

Lead-rubber bearings. Invented in 1974 by New Zealand’s Dr. Bill Robinson, the lead-rubber bearing is a modern example of base isolation, consisting of a lead core and alternately arranged layers of rubber and steel. In this design, rubber acts like a spring and remains soft during vertical loading.

Because the rubber itself features low stiffness, it can also flex sideways. To support high forces, the lead-rubber bearing is designed to feature high axial stiffness thanks to the steel layers. The lead core also absorbs energy caused by deformation and acts as a damping element. Flanges at both ends enable the lead-rubber bearing to be installed on existing structures, making this base isolation technique suitable for new and retrofit constructions.

Friction pendulum bearings. Friction pendulum bearings permit horizontal displacement of a supported structure and dissipate seismic energy through friction. The design consists of an upward-pointing, concave face located at the base of the bearing. During an earthquake, a supported structure will slide across the face and dissipate energy. Gravity forces the structure to return to a resting position at the center of the bowl-shaped bearing.

This solution is often combined with horizontal force bearings or dampers. Friction pendulums act as bearings that transmit vertical forces and absorb displacements and rotations. They are ideal for new construction but also improve stiffness and resistance to seismic forces when implemented in existing structures.

Air cushions. Another base isolation method is the air cushion. In Japan, many single-family homes feature air cushions because of the country’s high earthquake frequency. These houses are equipped with a sensor that continuously measures tremors. If a tremor exceeds a certain intensity level, a compressor pumps air into the cushion. Within seconds, the air cushion inflates and lifts the house by up to three centimeters, allowing the structure to absorb seismic shocks.

Seismic base isolation has been effectively mitigating the devastating impacts of earthquakes on buildings for centuries. In combination with vibration-damping systems, it is one of the most high-performing means of modern earthquake technology.

Ringfeder

www.ringfeder.com

Leave a Reply