The “intelligent coupling” features direct recording of mechanical data in the drive train, taking accurate measurements through user-friendly operation.

The “intelligent coupling” features direct recording of mechanical data in the drive train, taking accurate measurements through user-friendly operation.

Some of the ideas underlying the Industrial Internet of Things (IIoT) include the optimisation of operational efficiency and cost reduction in production and monitoring equipment and machinery. All kinds of production processes can be better adjusted to the prescribed re-quirements on the basis of the data collected and processed.

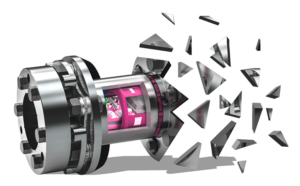

Collecting the data required in the field of drive technology is not always a simple task. Recording measurement data in a rotating drive train is often hampered by restricted installation spaces or difficulties gaining access with a networking cable. With immediate effect, R+W will be offering a hardware and software solution for this that offers user-friendly, versatile deployment in the form of the intelligent coupling.

This is an upgraded standard coupling, which offers additional measurement technology functions, thanks to integrated sensors that measure torque, speed, acceleration and axial load. This data is processed directly in the internal electronics while being simultaneously transmitted and presented in a wirelessly connected mobile device.

R+W’s intelligent coupling can be a smart alternative to a torque sensor, providing accurate measurements of various factors at a low price. The intelligent sensors permit data measurements without having to install an external measuring amplifier.

Determining force and torque in the actual driveline in real time can help to reduce or prevent outage and downtime, boosting system availability and reliability.

Leave a Reply