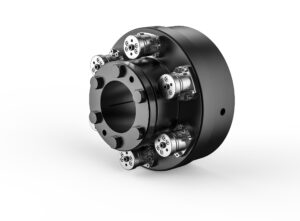

R+W has recently introduced two new smaller STN series safety couplings with conical clamping hubs, to bring heavy duty industrial style overload protection into midsize applications. The two new sizes, 2 and 5, cover disengagement torques ranging from 200 to 5,000 Nm, and shaft diameters from 45 to 80mm (1.750 to 3.125-in.).

R+W has recently introduced two new smaller STN series safety couplings with conical clamping hubs, to bring heavy duty industrial style overload protection into midsize applications. The two new sizes, 2 and 5, cover disengagement torques ranging from 200 to 5,000 Nm, and shaft diameters from 45 to 80mm (1.750 to 3.125-in.).

Taking advantage of the well-proven ball-detent safety element system, the driving and driven ends separate within milliseconds of a torque overload, releasing the motor inertia from the driveline, and reducing expensive repairs and costly downtime. The driveline is free to coast to a stop after disengagement, and re-engagement simply requires that a force be applied to the back sides of the plunger modules, either with a mallet or pry bar. Disengagement torque values are adjustable in the field and multiple ranges are available depending on the module configuration.

These safety couplings are designed with an output flange that can connect to a pulley or sprocket. Shaft to shaft connection methods are also available with either disc, elastomer, bellows, or gear coupling designs.

Leave a Reply