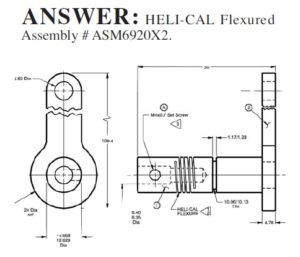

Application story 1:

Challenge: A Helical customer had planned to use the AE087 or AE100 to connect a potentiometer to a control lever. The operating atmosphere included both salt and dirt, plus high parallel misalignment potential. They wanted to use a “D” bore to fasten the lever to a shaft, then connect the coupling to the “pot.” Because of the small “D”, the cost increased beyond what the they were willing to pay. After some communication, the customer’s design engineer and Helical’s application engineer found a solution.

Challenge: A Helical customer had planned to use the AE087 or AE100 to connect a potentiometer to a control lever. The operating atmosphere included both salt and dirt, plus high parallel misalignment potential. They wanted to use a “D” bore to fasten the lever to a shaft, then connect the coupling to the “pot.” Because of the small “D”, the cost increased beyond what the they were willing to pay. After some communication, the customer’s design engineer and Helical’s application engineer found a solution.

Solution: By integrating the Helical Flexure and shaft, then press fitting a lever arm onto the shaft, the customer received a cost effective configuration. They also saved by having fewer parts to inventory and eliminating one subassembly. A second subassembly by the customer was eliminated by having enclosing the unit into a sheet metal covered box. This was the first time Helical was involved in this type of assembly work.

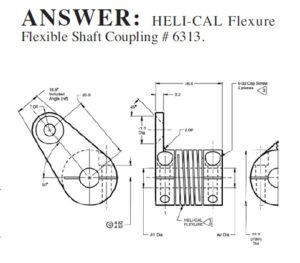

Application story 2:

Challenge: A manufacturer of racing engines needed to connect the individual throttle valves of an IndyCar race engine. The throttle valves regulate the flow of air into each combustion chamber on the fuel injected engine. This is then connected to the throttle linkage, which is controlled by the driver’s foot pedal. The flexible coupling is used to compensate for normal misalignments caused by manufacturing tolerances and distortion of the manifold containing all the throttle bores. Another concern was the extremely high vibration levels from engines running at 13,000 RPM, and forces caused by the high engine torque.

Challenge: A manufacturer of racing engines needed to connect the individual throttle valves of an IndyCar race engine. The throttle valves regulate the flow of air into each combustion chamber on the fuel injected engine. This is then connected to the throttle linkage, which is controlled by the driver’s foot pedal. The flexible coupling is used to compensate for normal misalignments caused by manufacturing tolerances and distortion of the manifold containing all the throttle bores. Another concern was the extremely high vibration levels from engines running at 13,000 RPM, and forces caused by the high engine torque.

Solution: The most difficult problem the flexible coupling had to overcome was the vibrational forces and twisting caused by the high torque of the engine, in addition to the normal tolerances and misalignments in the manufacture of the manifolds. These units have been tested and proven.

Helical Products

www.heli-cal.com

Leave a Reply