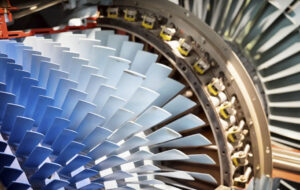

The IHI Group, one of the largest engineering and manufacturing companies in Japan, specializes in large-scale power and construction projects. One aspect of its business is to take jet engines that were originally designed for aerospace applications and adapt them to generate electricity in landbased, combined cycle gas turbine (CCGT) power plants. These efficient aeroderivative engines tend to use more advanced materials than industrial engines, which often allow them to operate at higher temperatures.

The IHI Group, one of the largest engineering and manufacturing companies in Japan, specializes in large-scale power and construction projects. One aspect of its business is to take jet engines that were originally designed for aerospace applications and adapt them to generate electricity in landbased, combined cycle gas turbine (CCGT) power plants. These efficient aeroderivative engines tend to use more advanced materials than industrial engines, which often allow them to operate at higher temperatures.

Two crucial components within a new CCGT installation are the couplings that connect the rotor shaft of the turbine to the gearbox and the couplings that connect the gearbox to the generator. The latter, known as the low-speed coupler, also acts as a safety device that protects both the turbine and the gearbox in the event of an overload situation. IHI required a matched pair of couplings that were capable of transmitting the immense power (up to 50 MW) of the General Electric LM6000 aeroderivative gas turbine. And they had to be designed and manufactured in approximately 14 weeks to meet installation schedules. IHI worked closely with Bibby Turboflex to develop a set of high-performance couplings that could be simply manufactured to suit each individual application.

The engine rotates at 3,600 rpm and the high-speed coupling, which is typically around 3.5 metres long, connects the turbine to the gearbox – that reduces the speed to 1,500 rpm. The reduction in speed equates to an increase in torque, which means that the low-speed coupling must be built to transmit the high torque levels created by the gearbox. Both couplings are designed within API 671 which requires a very high level specification and traceability for the components.

The low-speed coupling employs a set of shear pins that provide a simple, effective and precise method of disconnecting the drive system in the event of an overload.

Altra Industrial Motion

www.altramotion.com

Leave a Reply