Many types of shaft couplings are used with various production equipment, which requires high productivity.

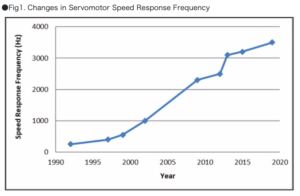

High-torsional stiffness couplings such as Disk type (Pic1) and Bellows type (Pic2) are primarily used in applications that require high positioning accuracy. On the other hand, recently, the speed response frequency of servomotors is increasing (Fig1), the vibration by hunting often occurs, resultantly we cannot use the motor with its maximum performance. Therefore, we need to suppress the performance to reduce vibration when using fully metal couplings.

There are Elastomer type couplings (Pic3) which have elastomers that absorb vibration using rubber and not suppressing motor performance. However, these Elastomer type couplings do have a problem; they have lower torsional stiffness when compared to Disk type or Bellows type. As a result, sometimes the Elastomer type is not good for strong cutting resistance applications such as lead screws of machine tools.

Hence, a big goal for coupling makers is to provide a coupling that can maintain high torsional stiffness and enable vibration absorption in the same coupling. In the past, one would have to choose between high torsional stiffness and vibration absorption functionality.

Fig1. Changes in Servomotor Speed Response Frequency

Fig1. Changes in Servomotor Speed Response Frequency

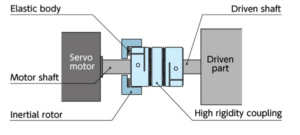

The dynamic vibration absorber is a mechanism that suppresses the coupling’s vibration when effected by the resonance phenomenon by joining the vibrator (coupling body) and supplementary inertial rotor through the elastic body. The following Fig2 shows the construction.

●Fig2. Construction of “XGHW”

NBK

www.nbk1560.com

Leave a Reply