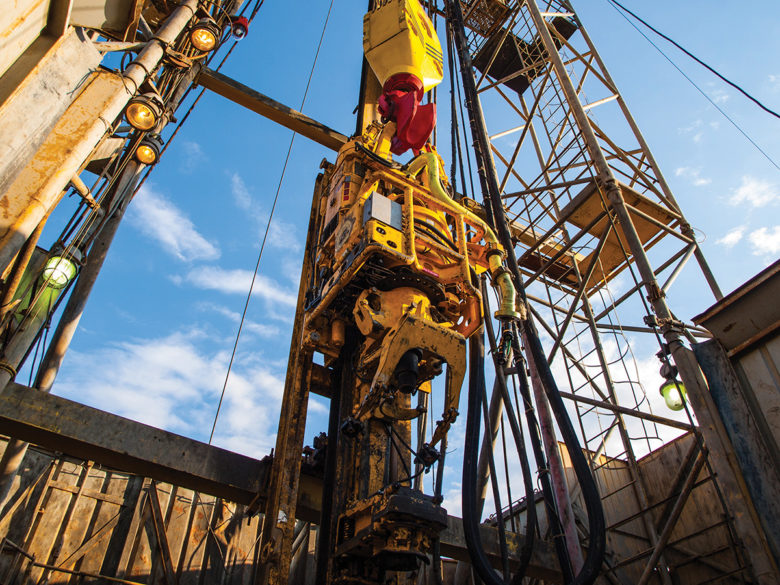

The top drive couplings are used to connect the drive motors and gearbox to the drill string. To meet the customer’s demanding specification requirements, Ameridrives supplied a custom 11-in. diameter gear coupling with a peak torque rating of 397,225 in.lbs. (44,880 Nm).

Amerigear fully-crowned gear teeth provide operational benefits including maximum load carrying capacity with minimum size, maximum reliability, and long life. Optimum separation of gear meshes permits high parallel offset capacity. Units feature accurately machined medium carbon steel hubs and sleeves. Positive-type O-ring seals keep lubricant in and contaminants out.

Amerigear

www.ameridrives.com