Located in the greater Houston area, GPM Pump and Seal is a provider of pumps, pump parts, mechanical seals and complete pump systems for oil and gas, petro-chemical, mining, water, wastewater treatment and other applications. They also specialize in pump and mechanical seal repair for all major OEMs.

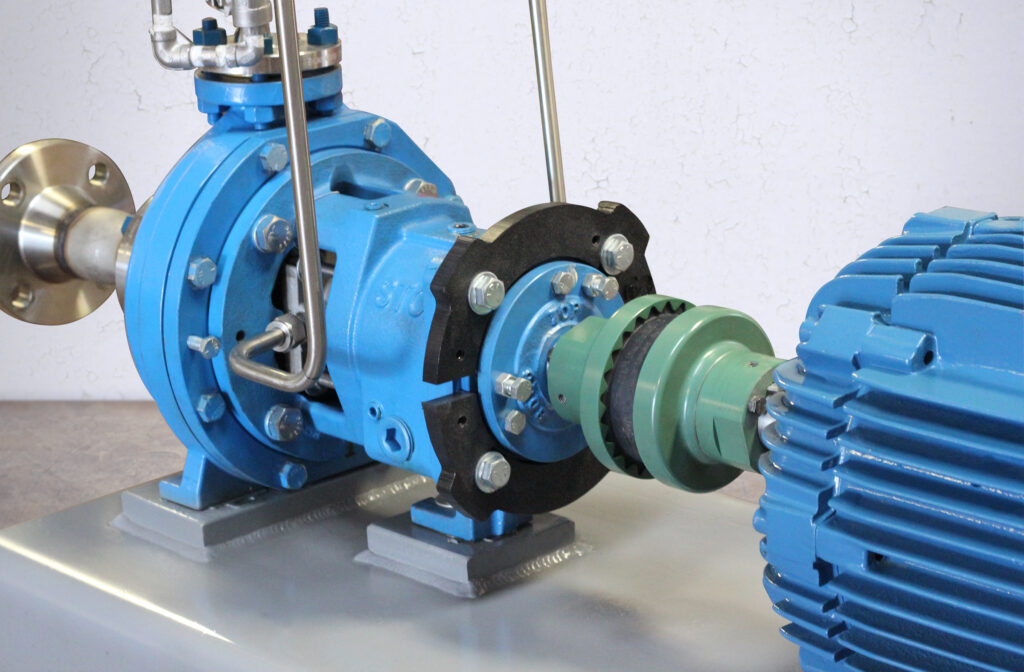

Elastomeric couplings are the industry standard for GPM’s market. Elastomeric couplings can accommodate the moderate misalignment that inevitably occurs in real-world applications due to pipe strain, thermal loads, settling baseplates, and various other causes.

GPM started specifying TB Wood’s Sure-Flex couplings several years ago. “Engineers often have issues with burs and shaft bores on some of the lower-quality couplings,” said Jon Boultinghouse, Sales & Operations Manager at GPM.

The Sure-Flex Plus coupling’s new elastomeric sleeves performed better and were more durable due to improvements in proprietary EPDM and Neoprene materials.

“We met with the GPM team to discuss the real-world benefits of EPDM and Neoprene sleeve materials. Our improved rubber compounds offered a 30% increase in torque ratings when compared to previous sleeves,” said John Smihal, Product Manager – Elastomeric Couplings at TB Wood’s. “This performance improvement lets an application use a smaller size coupling at an average of 25% cost savings.”

Application Example:

20 HP at 1750 RPM, 1.625-in. x 1.375- shafts

Original Sure-Flex Coupling Selection: Size 8S

New Sure-Flex Plus Coupling Recommendation: Size 7S

List Price savings: 25%

For GPM, the coupling line provided torsional flexibility, while the 4-way flexing action absorbed all types of shock, vibration, misalignment and end float. The couplings have 7° to 21° torsional wind-up (depending on sleeve material), and torque ratings up to 8,20 kNm (72,480 in.lbs.). The units also require no lubrication and no maintenance.

“We use couplings on almost all of our pump applications. Picking the right size is important,” said Boultinghouse. “A balancing act is required to size the coupling large enough, with enough service factor to work effectively, but also not too large as to incur unneccessary cost, like larger guards, skids or baseplates.”

GPM chose to use the couplings on all the non-close-coupled pump units they build. The most significant impact of the new couplings was on their ANSI pump packages. The ability to drop-down a coupling size helps them compete on large projects.

The Sure-Flex Plus also helped with GPM’s smaller Group 1 ANSI pump packages. Those configurations typically have a short pump shaft along with clearance issues associated with some types of labyrinth bearing seals.

“These conditions make it difficult to remove the coupling’s center sleeve element while performing a motor bump test. This is especially challenging when a larger horsepower motor is used, that requires a larger coupling,” Boultinghouse explained. “Dropping down to a smaller size coupling is a huge benefit, especially for maintenance operators.”

Sure-Flex Plus sleeves are interchangeable with existing flanges, supplying true “drop-in” performance. With a 30% torque rating increase, the enhanced EPDM and Neoprene sleeves not only lets coupling users replace their couplings with a one-size-smaller Sure-Flex Plus coupling.

TB Wood’s

www.tbwoods.com