In today’s rapidly advancing technology landscape, machinery and equipment must operate at maximum efficiency and with minimal downtime. Carefully selected components such as universal joints can prevent scores of machinery problems and help optimize operations.

By Rita Nolan | Belden Universal

In most cases, sourcing universal joints require some degree of customization. Joint selection is therefore most successful when all aspects of the application are discussed with the component manufacturer. Engineering and production teams can then specify the most appropriate product based on well-defined parameters. The OEM or end user should be involved at every design stage to ensure requirements are met.

Consider operational and environmental factors: The nature of application — including operating speed, angle, torque and environmental conditions — must be properly assessed during the initial phase of joint selection. Certain types of universal joints are better suited for handling heavier loads … others excel on axes run at high speeds over longer periods of time. Applications with abrupt stops apply additional force to the component that also needs to be considered.

The operating environment is another vital factor for joint selection. Dust or abrasives for example can lead to premature wear and component damage. If the joint is exposed to heat, chemicals or washdown fluids, corrosion and failure of the lubrication can lead to universal joint failure. In these instances, special materials and component protection are necessary.

When to use single or double universal joints or drive shafts

The main aspect for selecting the joint configuration is the type and extent of misalignment between the driving and driven shafts. Angular misalignment occurs when the driving and driven shafts are positioned at an angle to one another. Axial misalignment is the horizontal distance between the two shafts. Parallel misalignment is the parallel offset or movement between shafts.

- Single joints can compensate for angular misalignments of up to 45°.

- In contrast, double joints and drive shafts can compensate for up to 90° angles — 45° per joint) or compensate for parallel misalignment.

Drive shafts are essentially elongated double joints — suitable for compensating parallel and angular misalignments as well as overcoming greater axial misalignments.

Typical drive shafts feature a telescoping expandable middle portion that also allows for easy replacement of the assembly.

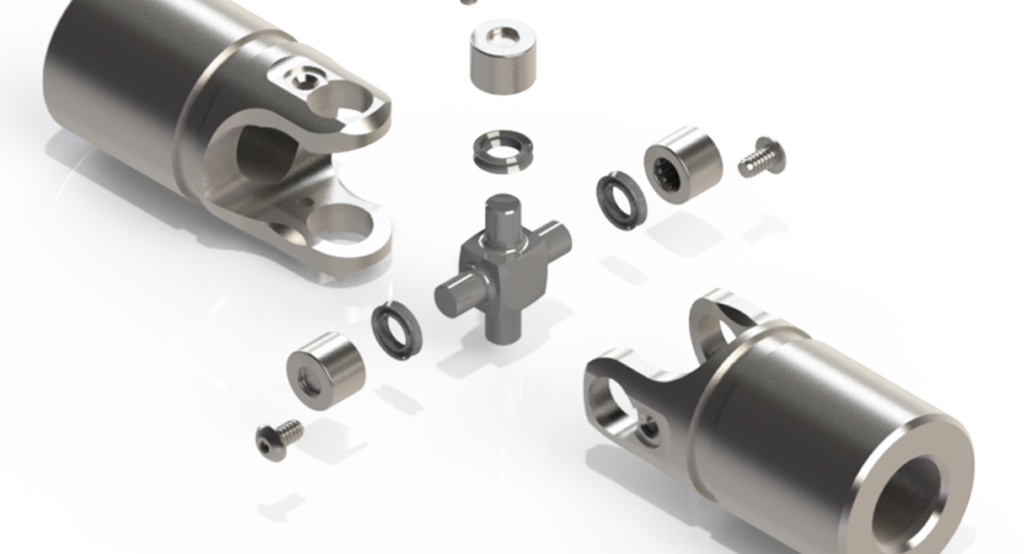

Friction bearing versus low-friction bearing components

The term friction bearing refers to the friction created between the moving components of the central connector during operation. The higher the friction, the more stress and wear asserted onto the joint — in turn resulting in heat, premature wear, and loss of precision. Friction-bearing joints operate with significant friction between the pins and the block of the joint. They are suitable for many standard applications and can carry high loads at moderate bearing speeds.

Lubrication can help reduce friction, heat generation, and wear — in the form of regular re-lubrication or oil-drips as well as grease-packed or oil-filled boot covers fitted to these joints to extend their expected life.

Needle-bearing universal joints use roller bearings at the contact points between pins and yokes, which significantly lowers friction, heat, stress and wear on the moving components. As a result, needle-bearing joints can sustain higher operational speed and precision for extended periods of time. Needle-bearings can be packed with lubricants and sealed for the lifetime of the joint; a method requiring less space and lubrication than the addition of lubricant-retaining boots. For these qualities, needle-bearing joints are suitable for high-precision, high-speed applications, such as automation and robotics.

Durability considerations include rpm, angle, and backlash

The durability of a universal joint is largely determined by the transmitted torque, angle of operation, and the rotational speed (rpm) of the driven shaft. Any combination of high torque, angle, and rpm values will effectively increase stress on the joint.

As the angle of operation increases, the U-joint pins oscillate in the bores in a greater magnitude — resulting in increased movement and wear between the bearing components. Excessive torque can cause the joint to break … and an excessive speed and angle at an acceptable torque may cause lubrication failure. That in turn leads to increased friction, heat generation, and wear. It is therefore crucial to identify typed of universal joint to avoid failures during operation.

Technical data and calculations for specific torque and speed can also aid in the size and type selection of the universal joint. Information pertaining to the acceptable amount of torque and torsional backlash (also called play) for a given application should inform the design and manufacture of the universal joint employed on that axis.

Universal joiont materials and coatings

Special applications often require carefully selected materials to deliver high strength, improved corrosion and wear-resistance or other desirable qualities. Alloy steel is typically the strongest and most widely used family of metals for universal joints.

Alloy steel universal joints are capable of handling high-torque applications and can be further strengthened by hardening. 300-series stainless steel is commonly used in sterile, sanitary and corrosive environments. Specialty stainless steel may be necessary for extreme corrosion or temperature resistance. Titanium, bronze, brass alloys, and nitrogen-strengthened materials can deliver additional improvements with regards to strength-to-weight ratio, wear, or corrosion resistance. Product qualities can be further enhanced by applying special coatings, such as nickel, zinc, cadmium, MoS2, PTFE, black oxide and finishing methods such as anodizing, polishing and surface passivation.

Mechanical quality, testing, and certifications for U-joints

Many customers’ quality requirements call for the highest standards in manufacturing — most commonly ISO9001 or AS9100 certifications. It is vital that the quality system is integrated into all aspects of the manufacturer’s operations, with materials and hardware sourced from suppliers complying with the same standards. For new product development, the design concept can be further validated using backlash testing as well as dynamic and static life tests.

For more information on universal joint selection and customization, visit Belden Universal at www.beldenuniversal.com or call (708) 344-4600.

You may also like:

Twin Spring Coupling releases the TSC150, a hybrid flexible coupling…

Ruland Manufacturing to distribute standard line of Belden universal joints

June Robotic Summit: Register now and we’ll see you in…

How flexible shafts improve flight

Belden Universal achieves AS9100C aerospace quality certification