Two industry trends could spur change in the application of couplings over the next few years. The first relates to technology improvements for the components themselves. Here, advanced materials are improving couplings in an array of industries. The second is economics-influenced market growth. Expect to see enduring gains in the use of motion designs through 2020.

Technology sees smaller designs and application-specific offerings

We asked industry experts to weigh in on what they see in the industry. Most identified new modes of IoT connectivity, size reduction for designs into which couplings go, and application specific designs as top trends.

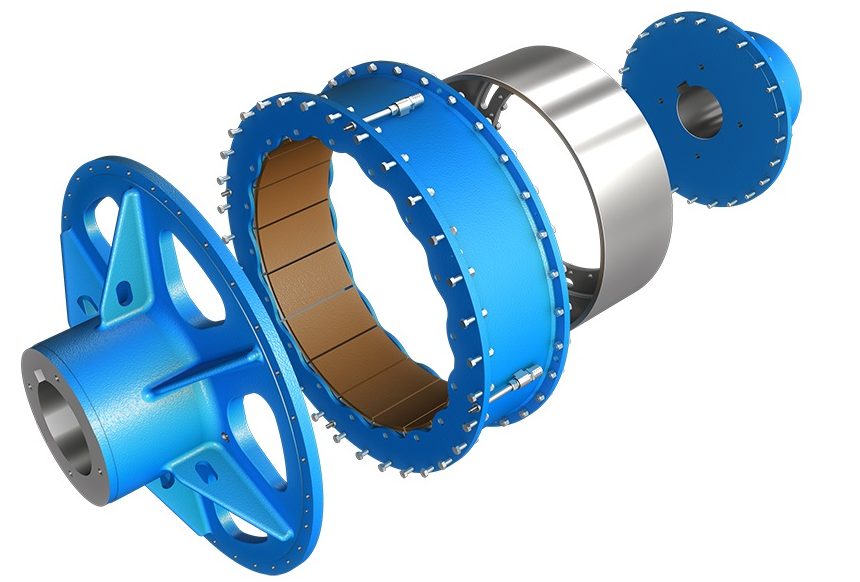

Mike Williams • Eaton’s Airflex Product Manager: What we see in our little sandbox so to speak is people asking for temperature sensing, people asking for some more automation, keeping personnel, the workers, out of dangerous areas by having remote control panels.

That’s one of the key components of our torque-limiting coupling. We have a control panel that keeps the operator outside of where the motor and the shaft are. You can do all the starts, resets and restarts from outside. There is no lockout-tagout needed because you do not have to enter that area. I think safety drives a lot of that. I think also finding out the sweet spot of operation also tends to demand more metrics to be gathered and more data to be acquired in order to find the most efficient way to operate.

Our product line is also very custom. I would say we probably say 50% of our products, maybe even a little bit more, are based on a customer coming to us and saying, ‘Look, we have this grinding mill,’ for instance and ‘Here is the power of the mill. This is what the load is going to be. This is the type of motor we’re using.’ We custom select and build that product for them. We have some standard offerings. We take those standard offerings and adapt them with different support functions.

What you’re starting to see is engineers not just wanting a custom coupling, but maybe a custom solution. Maybe they want a package solution that shows your coupling with your motor, or a full power transmission package that an engineer can just plug and play into an overall piece— a bigger piece of equipment. They can go right to the experts, get a solution and move on with the rest of the equipment.

Mike Parzych • GAM Enterprises: The mass customization and personalization trend in the consumer industry has been a trend that GAM has been close to for many years now. Even with all of the conformance standards out there in our industry, customer constraints and application requirements introduce variability into the machine design, which often cascades throughout the entire system, resulting in the need for a special design at the component level.

While in theory it is an easy concept and many companies say they can accommodate such custom designs, the execution is extremely difficult from a manufacturing standpoint as many of the systems and processes are designed for efficiency, repeatability, and reliability. Once a custom product or special feature is introduced, the entire production flow can be disrupted. Maintaining quality and repeatability in this scenario is extremely difficult, thus systems and processes must be designed from the ground up to truly embrace this concept. All aspects of the business must be in sync from supply chain, to engineering, all the way down to the machinist on the floor.

Market trends: Increased use of couplings

Mechanical-coupling sales are ubiquitous enough to track the global economy — and at present, the economy is being kind to couplings. Expansion in Mexico, Indonesia, Nigeria and Turkey (or MINT nations) are expected to show growth for couplings. China, Brazil and Russia should also show growth albeit slower. Developed economies will likely offset the growth of the other regions but not enough to stagnate forward momentum. For more information from Transparency Market Research, visit this deep link to couplings-market specifics on transparencymarketresearch.com.

Leave a Reply