Good vibrations? Not really. When you need a coupling to handle impulse loads, misalignment, electrical isolation and more, jaw couplings are the most common choice. A staple in semiconductor, medical, solar and many other applications, jaw couplings are nearly everywhere. And so are the online videos featuring them. Here, we break down some of the […]

Jaw

Drive couplings added to SureMotion line

Rotating shaft-driven mechanical components are commonly used in all forms of machinery that perform the various processes and functions of modern industry. While perfect alignment of shafts and rotating components is desired, shaft ends can often be misaligned. This misalignment places stress on shafts and related parts, which can result in early failure of both. […]

Motion systems application examples: Couplings

By Mike Santora Couplings are simple yet precisely engineered devices that connect shafts to transmit torque and compensate for misalignments. But many variations of coupling designs exist to complement machine dynamics and meet specific application criteria. Couplings are either torsionally rigid or flexible. Flexible couplings compensate for misalignments, while rigid designs handle drive components already […]

What is a vibration-damping safety coupling?

Malfunctions happen. And when they do, damage and repair costs follow. Safety couplings are the mechanical connecting elements designed to protect other machine components surrounding a drive system. When a malfunction occurs, safety couplings help keep the damage to a minimum. Safety couplings include torque limiters to handle mechanical overload. In disconnect types, torque limiters […]

Miki Pulley introduces its Jaw Type shaft coupling to the U.S. market

Miki Pulley is introducing its Jaw Type, High RPM coupling for direct sale to OEM’s in North America. This ALS-SGN model handles speeds to 22,000 RPM. Designed for use in the main spindle shaft on CNC machining centers, the Miki Pulley ALS-SGN coupling uses unique taper-lock hubs. This hub design ensures concentricity and rotational balance […]

Jaw coupling overview – features, benefits & design basics

Jaw couplings are a general, all-purpose industrial power transmission device that operates in a range of temperatures, handles angular misalignment and the accompanying reactionary loads, resists chemicals and has good speed and dampening capabilities. A basic jaw coupling is made of three parts: two hubs, generally bored to a clearance fit tolerance, and an elastomeric […]

Pick the right coupling for each high tech application

Selecting the right coupling for your application is critical to system safety and reliability, says Ruland Manufacturing Co. Inc., Marlborough, Mass., which manufactures a diverse couplings product line while providing technical support and application experience. Ruland’s coupling line includes rigid couplings with precision honed bores and five types of zero-backlash couplings: beam, bellows, disc, jaw, […]

Lovejoy and VibrAlign develop partnership, educational series

Lovejoy Inc., Downers Grove, Ill. and VibrAlign Inc., Richmond, Va., have developed a strategic alliance to create improved educational opportunities for users of couplings and shaft alignment tools. In addition, the two companies are partnering to bring a traveling educational series to several locations in the next two months. Founded in 1900, Lovejoy specializes in […]

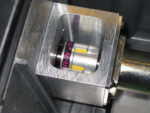

Robust jaw couplings make for easy water testing

Testing water samples is an important and critical business, so when Hach Co., Loveland, Colo.—a provider of water quality testing and water quality analysis—was designing one of its signature samplers, it wanted a design that was maintenance free and wouldn’t cause any problems. That’s why Hach turned to R+W America, as it worked on the […]

Zero Backlash Jaw Couplings from Ruland

Ruland offers zero backlash jaw couplings for the demanding requirements of start and stop machine vision systems used in industries such as semiconductor, medical, solar, and packaging. The dampening characteristics of Ruland’s jaw couplings reduce settling time and shock loads, making them ideal for these environments. Jaw couplings are a three piece design comprised of […]