Characteristics The most popular flexible shaft coupling in Japan that is compliant with JIS B 1452-1991 “Flexible Flanged Shaft Couplings”. Simple structure comprised of a flange and coupling bolts. Easy-to-mount. Bushings can be replaced just by removing coupling bolts. This makes maintenance and service easy. While it absorbs misalignment such as eccentricity and argument, it […]

Flexible

Twin Spring Coupling releases the TSC150, a hybrid flexible coupling unit

Twin Spring Coupling recently announced the release of its 3rd product line, the TSC150. Twin Spring Couplings patented design allows the coupling to do the job of two different coupling technologies in the one, as well as offering a truly maintenance free product as it contains no bearings. The Twin Spring Coupling TSC150 can handle high […]

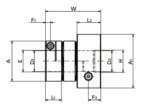

NBK’s FCL-BUSH flanged shaft coupling

The most popular flexible shaft coupling in Japan that is compliant with JIS B 1452-1991 “Flexible Flanged Shaft Couplings”. Simple structure comprised of a flange and coupling bolts. Easy-to-mount. Bushings can be replaced just by removing coupling bolts. This makes maintenance and service easy. While it absorbs misalignment such as eccentricity and argument, it prevents […]

Twin Spring Coupling launches a new hybrid flexible coupling

Twin Spring Couplings patented design allows the coupling to do the job of two different coupling technologies in the one, as well as offering a truly maintenance-free product as it contains no bearings. The Twin Spring Coupling TSC150 can handle high speed/low misalignment, it can also run at lower speeds and higher misalignment like the […]

NBK Flexible Couplings — vibration-absorption capable disk type

The vibration-absorption capable disk type XGHW-C has a dynamic vibration absorber on the high rigidity disk. It enables vibration absorption and use of higher gain levels when compared to regular disk types, thereby also allowing a shorter stabilization time. The vibration absorption function reduces the amount of parameter adjustment work, and lowers the time required […]

“Paraflex” Pin-Hub couplings from Miki Pulley

Miki Pulley announces Introduction of its “Paraflex” Pin-Hub Couplings for direct sale to OEM’s in North America. Key features of these couplings include high allowable misalignment, low backlash and resonance dampening. With a pin-bushing type design, these Paraflex Couplings are available in two models. The CPU model has a maximum torque of 25 Nm and […]

The eight best ways to wreck your coupling driven system

Keeping a servo-driven system running at peak efficiency is no simple feat. Misunderstanding performance criteria such as misalignment, torque, or RPM can be all it takes to cause a critical failure. The following are the eight best ways to consistently sabotage or damage your coupling driven system (and how to avoid them in the future). […]

Curved beam flexible coupling from RoCom Couplings Corp

Rocom’s one piece, double taper, multi overlapping, curved beam flexible coupling is the patented result of years of testing. The beams are double tapered so that they are thick at the OD and thin at the ID in ratio to the circumferential lengths. They are thick at the hub end of the beam and thin […]

Kop-Flex KOP-GRID couplings

The grid design functions as a resilient coupling by damping torsional vibration and cushioning shock loads. This results in reduced vibration at the output end of the coupling. Peak loading is reduced, for smooth torque transmission, to help protect connected equipment from potentially damaging vibratory loads. A second function of the grid design is that […]

XGT2 high-gain rubber type coupling: productivity and stabilization time

High-gain flexible coupling which surpasses XGT-CXGL-CXGS-C in performance. This is a single-piece construction with the two aluminum hubs molded with high-gain rubber. The optimal damping and rigidity design enables realization of even greater servomotor gain, leading to reduced stabilization time. Technical information⇒Productivity and stabilization time Suppressing speed unevenness control during stepping motor operation is effective.⇒Suppressing […]