Zero-Max Schmidt Offset Couplings provide machine designers with a proven method to ensure machines operate with constant phase accuracy and constant speed throughout the rotation and cycle of the machine.

Zero-Max Schmidt Offset Couplings provide machine designers with a proven method to ensure machines operate with constant phase accuracy and constant speed throughout the rotation and cycle of the machine.

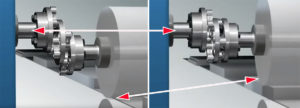

Where precise performance of system components is required and reduced machine size is important, these Offset Couplings provide a solution. They are available in sizes with a large range of parallel misalignment capacity with shaft displacements of 0.156 to 17.29-in. and torque capacities from 55 to 459,000 inch-pounds. Providing length space savings, they eliminate radial vibration from one end of the offset coupling to the other end. Most important, the Schmidt Offset Couple allows for dynamic misalignment changes with no performance loss.

Applications include:

• Printing And Paper Converting Systems: Schmidt Offset Couplings provide constant velocity for accurate print registration and eliminate radial vibrations for uniform coatings on paper. They facilitate roll diameter changes, roll washup, and allow print rolls to swing easily in and out of the press print stations.

• Metal Processing Systems: Schmidt Offset Couplings connect to nip rolls for accurately feeding steel web material for processing. They open easily for threading in new material and allow for different material thicknesses. They allow downforce on a nip roll while isolating the downforce from the connecting motor/gearbox. They are a good choice for uncoilers, coil straighteners, and roll forming systems among other types of metal processing equipment.

• Automated Assembly Systems: Schmidt Offset Couplings open up many new possible applications for automated systems including packaging, pharmaceutical, food processing and much more. Their unique design allows for critical machine space savings on production floors.

To see the unique capabilities of the Schmidt Coupling, visit this Zero-Max video:

To see the unique capabilities of the Schmidt Coupling, visit this Zero-Max video:

https://youtu.be/zVt1tvD7rqk

In addition to Schmidt Offset Couplings, Zero-Max provides a full range of motion control components. The company has created solutions to servo motion control problems worldwide with shaft couplings, adjustable speed drives, and keyless shaft bushings. Strategic distribution points are located throughout the world backed by application specialists to provide engineered solutions for most motion control requirements.

Zero-Max

www.zero-max.com

Leave a Reply