By Joyce Laird, contributing editor

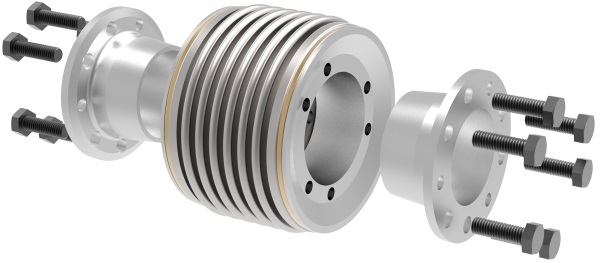

Understanding the application to create a perfect match is always the first step in any process. Understanding the parts that go into that application are the key to that perfect match. So, first it is important to understand what a conical clamping hub is.

Matching this technology to the application

The first thing to look at is how does this affect the coupling integrity. The conical clamping design relies on frictional clamping force to transfer torque, resulting in a backlash and maintenance free solution for specific applications.

“Due to the high clamping forces generated by the hub, conical style couplings are used in high torque and shock load applications,” Parzych says. “Also, because they are rotationally symmetric, they are often used in high speed applications. Examples of industries that benefit from this type of assembly include machine tool, printing, converting, and packaging.”

Installation tips

“Assembly and dis-assembly of a conical clamping style coupling can be more time consuming compared to a radial clamping (single bolt) style coupling,” Parzych says. “Conical hubs have several bolts that need to be tightened gradually in a crosswise sequence to ensure even draw of the bushing and mating shaft to the hub. Because the mounting bolts are positioned axially to the hub and concentric with the shaft, it can often be difficult to get access to properly tighten the bolts.

Advantages are Worth the Added Work

Parzych notes that even though the initial assembly requires a bit more work, the mechanical advantage gained from the conical taper means that the bolts require considerably less tightening torque compared to a single radial clamping bolt in order to reach the rated torque level.” Therefore, the benefit for specific applications is well worth the added time in perfecting the assembly detail. If in doubt regarding whether this type of assembly is the right fit for your application, Parzych says that it is always best to contact an expert source rather than to experiment.

GAM

www.gamweb.com