R+W, which is known for flexible shaft couplings for servodrives, is expanding its offerings to include flexible disc pack couplings. Its new series of Survivor couplings is best suited for demanding industrial power transmission systems.

The Bensenville, Ill.-based company has spent more than two decades creating flexible bellows couplings that offer high torsional stiffness, low moment of inertia, and continuous symmetry, all of which lend themselves to motion systems involving rapid indexing and high precision positioning. But as the company has grown, it has seen the need for a different type of fatigue resistant metallic coupling.

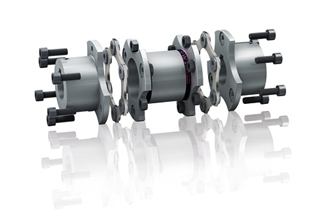

Three models are available in the company’s LP series of Survivor couplings, including the single and double flex LP1 and LP2 disc pack couplings with keyway and set screw mounting; the double-flex LP3 disc pack couplings with conical clamping ring; and a special API 610 version (LPA) which meets all of the stringent requirements for critical centrifugal pumping applications.

Two standard spacer lengths are available for each double flex version, with full customization of dimensions and materials available, depending on the specific application requirements. As with all R+W couplings, the LP couplings are available with either imperial or metric bore diameters ranging from 18 to170 mm (~3/4 to 6-5/8 in.) and with torque capacities ranging up to 20,000 Nm (177,000 in-lb).

R+W highlights how material fatigue results from a certain number of stress cycles at a certain stress amplitude. In a flexible coupling this essentially means the number of shaft rotations at certain levels of misalignment and torque. In the case of ferrous materials, when the stress amplitude is known and kept below the fatigue limits of the flexible element in the coupling (i.e. the misalignment and torque ratings), any number of cycles can be tolerated without fatigue. The goal is infinite life for the product.

More than just servo driven machinery demands reliable performance. Designed to protect drive shafting, bearings and gears from stress related to misalignment and structural changes, a flexible shaft coupling is subject to a very large number of bending cycles in its life. More traditional designs require either periodic lubrication or replacement of wear parts to help relieve this stress. But frequent maintenance is simply unacceptable in some critical installations. Metallic flexible couplings are a category which is typically designed with the intent to fully eliminate wear, based on the principle of fatigue resistance.

R+W has been applying this concept to maintenance-free bellows couplings for many years. While the metal bellows coupling is often scaled up into the megawatt drive power ranges for applications which demand its specific characteristics, many industrial drive applications do not involve the dynamic motion profiles of servo systems, and tend toward continuous forward rotation. As loads become larger and drivelines more power dense, a different set of shaft coupling characteristics, such as those in the Survivor LP, can be more suitable.

R+W’s version of the steel disc pack coupling aims to offer infinite service life. They transmit torque across the disc pack assemblies purely by friction. A series of bushings are pressed together by R+W to assemble the disc packs, while precision locating features in the hubs and spacers present a concentric fit. The bolt assemblies are then tightened through the hubs, spacers and bushings to generate the necessary clamping pressure across the faces of the disc packs to transmit all of the power by friction. This purely backlash free friction fit serves to eliminate problems associated with stress concentration, backlash, and micro-movements, all of which can result from transmitting torque across the shanks of shoulder bolts. The frictional connection of the disc packs further increases service life, in addition to making the complete coupling assembly more torsionally stiff.

R+W America

www.rw-america.com