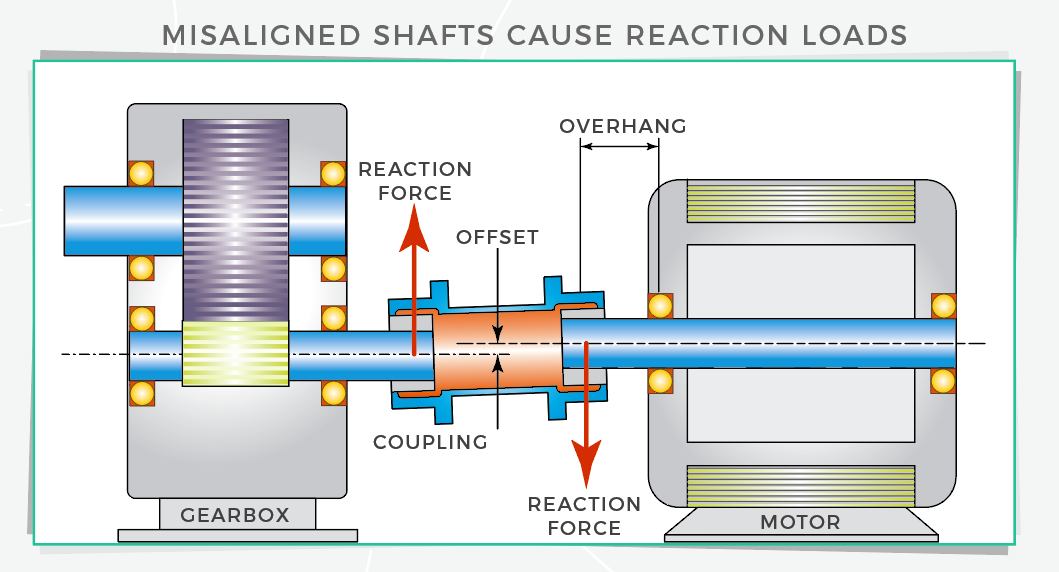

All flexible couplings compensating for misalignment cause reaction forces, and their effect is significant if misalignment is excessive. These often-overlooked reaction forces transmit to connected shafts and support bearings, and can cause damage to motion axes — especially on precision designs with delicate bearings and slender shafts. Though couplings get their compliance from elastomeric deflection, sliding contact, and flexing coupling members, here we focus on the types most common for motion designs employing stepper or servomotors.

Ultimately, reaction-force magnitudes depend on the level of misalignment and the coupling type in use. Bellows couplings, so-called membrane couplings such as disc couplings, and beam couplings have thin sections of various designs capable of radial flexing. Resistance to misalignment — a spring-rate reaction defined as a force per unit of deflection — increases proportionally with shaft deflection. Because these couplings bend to accommodate misalignment, reaction force depends on the thickness of the flexible element.

Reaction forces from beam and bellows couplings

Bellows and beam couplings (with the latter covered in the next section) have multiple coils or convolutions, so work as flexible shafts that sweep through complementary bows as the mode of misalignment compensation. Torque transmission is through members in shear, so the convolutions can be thin and keep radial forces low while maximizing torsional stiffness. In contrast, membrane-coupling variations transmit torque via bending members, so need thick members to get high torsional stiffness. Such couplings’ bending (through complementary directions) also compensates for shaft misalignment. The catch is that these torsionally stiff couplings can induce high radial-reaction forces if excessive misalignment is present.

Recall that radial-force magnitude largely depends on bend severity. So minimizing bending angles reduces the detrimental forces on support bearings (though can reduce misalignment capacity, too). Some membrane couplings address more misalignment when equipped with a central member between the flexible members, as the added distance imparts an ability to turn while making shallower bends (and lower radial forces) for a radial shaft offset. In fact, aforementioned beam and bellows couplings with divided flex-element arrays also sometimes leverage more distance between flexure points to get shallower bends for a given radial shaft offset. Short models can sometimes connect via an intermediate shaft.

Reaction forces from sliding-contact couplings

Now consider interlocking members of sliding-contact couplings such as Oldham and universal-lateral couplings. These transmit torque while mitigating shaft misalignment through lateral sliding. One reaction force depends on the friction coefficient between mating surfaces; the other depends on members’ rigidity modulus. So these couplings deliver torsional stiffness independent of radial reaction forces. A two-axis slider with bearing surfaces (called a floating member) engages and aligns one out of two hubs at a time to accommodate misalignment while maintaining torque transmission. Sliding friction induces radial forces independent of radial deflection; preloading (to prevent backlash) can spur some radial force under modest misalignment. That said, these sliding-contact couplings can tolerate large misalignment even while minimizing reactive forces.

Reaction forces from elastomeric couplings

In contrast, elastomeric couplings have myriad torsional-damping properties and transmit torque in shear, bending, and compression. Coupling class is key with this design: Some versions exhibit zero backlash while others rated for use in power-transmission applications can exhibit minute inter-hub rotation. Most variations transmit torque (and address misalignment) through compressible elastomeric-insert spiders trapped between jawed halves … and induce reaction forces when connecting shafts with excessive radial shaft deflection. Jaw designs can accommodate more misalignment (and minimize detrimental forces on the shafts’ support bearings) with softer elastomer spiders, though that sometimes reduces torsional stiffness.

Remember that if excessive misalignment is a concern, consult with coupling manufacturers on the design. Their engineers may suggest design improvements; offer coupling types to resolve the misalignment without inducing unacceptable reaction forces; and supply charts of reaction forces that a given coupling is projected to induce under a given set of conditions.

Editor’s note 8.16.2017: Expect another followup piece soon on couplingtips.com to cover another option to address reaction forces and other issues — permanent magnet (non-contact) couplings. These are a setup sold by Magnetic Technologies of Oxford, Mass.

Leave a Reply