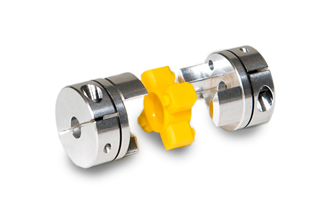

Selecting the right coupling for your application is critical to system safety and reliability, says Ruland Manufacturing Co. Inc., Marlborough, Mass., which manufactures a diverse couplings product line while providing technical support and application experience. Ruland’s coupling line includes rigid couplings with precision honed bores and five types of zero-backlash couplings: beam, bellows, disc, jaw, and Oldham.

Ruland’s couplings are used in many different high tech industries including semiconductor, solar, medical, food, packaging, printing, labeling, linear and petrochemical. Each industry requires couplings to have different performance characteristics. Beam and Oldham couplings are good choices for applications that require higher amounts of misalignment with zero-backlash performance, while bellows, disc, and jaw couplings are ideal for applications that require high accuracy, repeatability, and zero-backlash. Rigid couplings are a good fit across many industries, providing there is no misalignment, as they are the stiffest, most accurate, and available in the widest array of sizes, styles, and materials. Ruland couplings feature a balanced design that allows them to run at higher speeds with reduced vibration.

“Special couplings can be manufactured based on customer requirements if a standard offering is not suitable,” explains William Hewitson, Ruland’s Vice President of Operations. “Our engineers will work directly with customer engineering teams to build a coupling that meets specifications and minimizes cost.” Prior specials include custom bore tolerances and geometries, materials for high temperature and chemical resistance, custom screw sizes for installation standardization, 303 or 316 stainless steel coupling hubs for corrosion resistance, and many others.

Ruland’s complete product line includes a wide variety of shaft collars, including one- and two-piece clamp-styles, threaded, heavy duty, double wide, and keyed. Ruland has recently released quick clamping shaft collars for easy adjustment without tools, and washdown shaf

t collars for food processing and other hygienic applications. More new shaft collar styles will be released in 2013 to better match customer needs.

“All products are manufactured in our Marlborough, Massachusetts factory for manufacturing flexibility, control of proprietary processes, and to allow for a high level of service. Raw materials are sourced from specified mills to ensure the consistency, integrity, and performance of the finished product,” says Hewitson. “Just as an artist leaves their mark on fine art, we stamp the Ruland name on each of our shaft collars and couplings.”

All Ruland products are RoHS2 and Reach compliant.

For a comprehensive overview of Ruland couplings, read “What to look for in a servo coupling” written by William Hewitson.

Ruland Manufacturing Co. Inc.

ruland.com