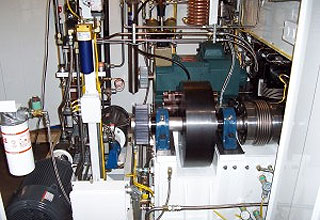

Michigan Custom Machines builds end of line functional test machines, primarily for the diesel and automotive industries. This particular application required a 400 lb flywheel to mimic the inertia of a diesel engine driveline. The flywheel was mounted to a shaft that needed to be coupled to a custom camshaft that is actuating a fuel injector.

One of the challenges was the stiffness of the coupling. We have found that if the coupling has wind up, even though it is zero backlash, it will affect how the test is performed by allowing the instantaneous rpm to droop momentarily within part of a revolution.

We used a Model BK1/6000/XX coupling. It was a custom model – the adapters were custom to fit the different shaft sizes and the shaft locks we used.

It was known when sizing this coupling that the BK1/6000/XX could not handle as much torque as a previous disc type coupling used, but the stiffness was higher. After installing the BK1/6000/XX, an instrument was used to see how much phase change is seen during operation from one side of the coupling to the other. The BK1/6000/XX showed 1/3 of the phase difference, or wind up, compared to the previous couplings used. This resulted in more consistent testing of the fuel injector.

R+W America

www.rw-america.com