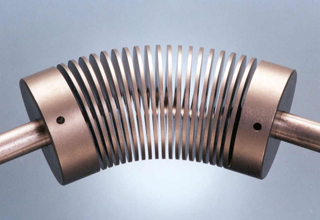

A beam coupling, sometimes called a helical coupling, consists of a single piece of material made flexible by the removal of material in a helical pattern along its length. As with all couplings, the purpose of a beam coupling is to transmit torque between two shafts, but unlike a rigid coupling, a beam coupling can accommodate angular misalignment, parallel offset and even axial motion, of one shaft relative to the other. The beam coupling also differs from other coupling types in that its one-piece construction prevents the backlash usually encountered by couplings made of multiple parts.

Beam couplings can be found in a variety of materials including titanium and acetal with stainless steel and aluminum being the two most common. The light weight of an aluminum beam coupling means they are suited for applications where a high level of responsiveness is needed. Stainless steel, on the other hand, while providing greater strength and torsional stiffness, has a greater mass and thus does not have the same level of responsiveness.